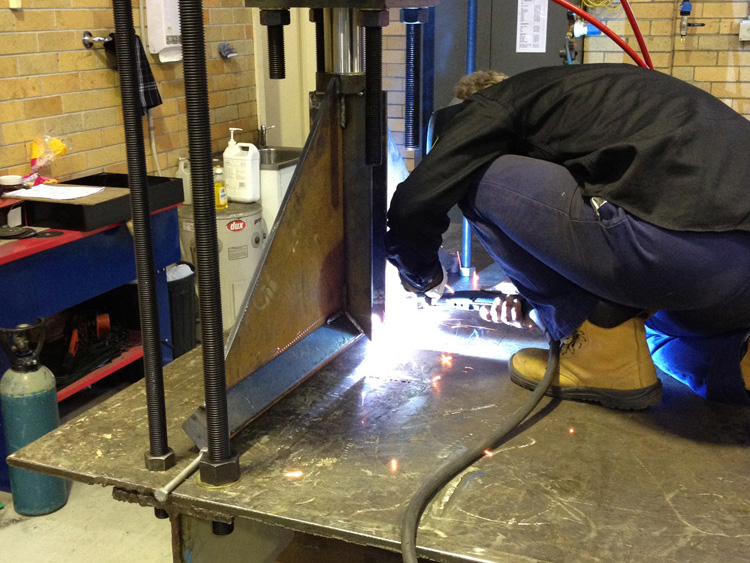

Our Fabrication capabilities include small and large structures that are put together by our qualified boilermakers and welders.

Steel Fabrication

Blasting and Painting

HV Engineers Newcastle can organise blasting and painting services to fulfil our customer’s expectations. Blasting and painting is carried out to Australian standards using applicable grit and paint.

We have a standard 3 coat painting specification that we use that provides a hardy surface coating that is accepted and proven in mining applications. However, we can provide a surface coating to any specification provided.